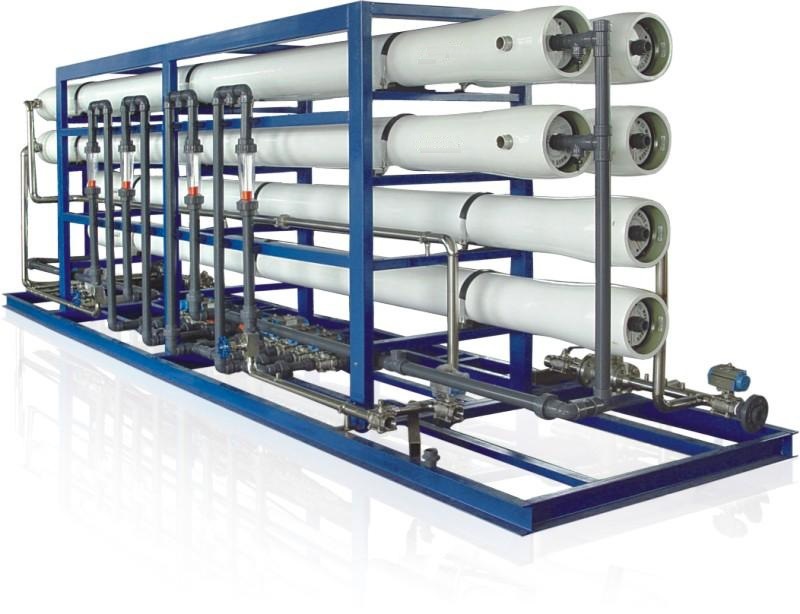

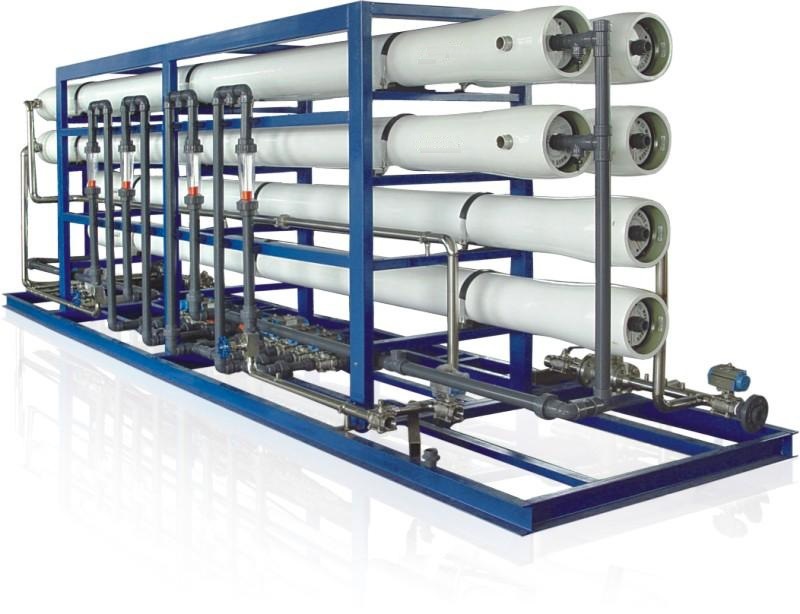

Until now, the anxiety of freshwater resources in 233 countries and regions around the world has not been alleviated reasonably. Declare that under such circumstances and standards, ultrafiltration membrane The fast way to enter the development trend. From the desalination equipment project in Africa to the largest water supply company in Asia, the water plant in the north of Yuexiu District in Guangzhou has been completed and put into operation. All types of ultrafiltration membranes have achieved great success.

It can be said that without the advent of ultrafiltration membrane with excellent performance, there would be no guarantee of water safety. From consumer ultrafiltration membrane water purifiers at home to industrial production ultrafiltration membrane sewage treatment projects, people's drinking water safety has been closely linked with ultrafiltration membrane.

From the structure of ultrafiltration membrane, tubular ultrafiltration membrane filter element, also known as column ultrafiltration membrane filter element, is the most common in daily life. In addition, strip, roll, hollow chemical fiber, curtain and other structures are also ubiquitous.

Take the ultrafiltration membrane commonly used in the municipal sewage treatment management center as an example. This ultrafiltration membrane belongs to the curtain type. In the dairy production and processing workshop, the ultrafiltration membrane used to respond to the solution belongs to the column type.

So far, the development trend of ultrafiltration membrane has evolved into dozens of models and specifications. According to different classification specifications, different ultrafiltration membrane modules are named differently.

According to the direction of the source fluid passing through, internal pressure film and external pressure die are two types; According to the industrial production model and specification of ultrafiltration membrane, 4040 and 4080 are two common types.

However, no matter what specifications are used to divide the ultrafiltration membrane, the ultrafiltration membrane manufacturer has consistent and persistent quality regulations on membrane components. The plugging rate of various types of ultrafiltration membranes must be controlled within 1%. Otherwise, the goods will be difficult to be recognized by the sales market.

In the final analysis, the most critical reason is that the characteristics of the membrane filament determine the final actual effect of filtration. If the problem of hole plugging cannot be properly handled in the whole process of manufacturing ultrafiltration membrane modules, the filtration characteristics of the filter element will be greatly affected.

In the production process of ultrafiltration membrane module, the most common production method is just the traditional thermal laser cutting. This kind of ultrafiltration membrane sawing production and processing method not only consumes a lot of power energy, but also has many shortcomings in the sawing accuracy.

When the production and processing method is selected to sawing, producing and processing ultrafiltration membrane components, not only the quality of the membrane wire laser cutting must be concerned, but also the hole plugging rate control of the membrane wire after the laser cutting is also a difficulty.

It can be said that the traditional sawing method for the production and processing of ultrafiltration membrane modules has long fallen behind the production and manufacturing regulations of the period. In that case, some ultrafiltration membrane module cutting machine manufacturers have developed a new type of membrane module cutting machine.

For this kind of newly launched membrane module cutting machine, after its introduction, it marked that the production and processing of all ultrafiltration membrane modules had taken a big step forward.

According to the technical parameters of the new membrane module cutting machine, this kind of ultrafiltration membrane cutting machine was based on the market demand at the beginning of the design scheme and was designed and manufactured strictly according to the market demand.

Therefore, the new membrane module cutting head machine selects the non heating cutting method to complete the fully automated cold laser cutting technology. In the case of specific production and manufacturing of ultrafiltration membrane modules, only the membrane modules must be placed on the feeding rack, and the main cutting parameters can be keyed in to complete the production and manufacturing of fully automated technology.

In addition, during the whole working process of the new membrane module cutting machine, because the design scheme of totally enclosed mask is selected for adding machine equipment, which promotes that the noise and film chips caused by cutting will be reasonably controlled in the effective range when the membrane module is sawed.

In terms of the purchase of membrane chips, if the machinery and equipment are modified with double dedusting equipment, then the environmental hygiene level of the production workshop in the work of the membrane module cutter can be reasonably guaranteed, and the company's employees are not likely to get sick due to the suction of membrane chips.

Naturally, in addition to the described main parameter characteristics, the most critical reason for dealing with the problem of continuous increase in the porosity of membrane plug is that the cutting accuracy of the machine itself is not qualified.

However, such problems will be more and more eliminated in front of the new membrane module cutting machine. Because this kind of membrane module cutting machine uses the ball screw linear module to transmit the driving force, and the precision of the main shaft bearing of the machine itself is 0.01mm.

The laser cutting precision of the ultrafiltration membrane module machined by the cutting head of this kind of ultrafiltration membrane module can be within 0.5mm. With the improvement of laser cutting accuracy, the plugging rate of the membrane wire itself is also controlled within the range of 1%.

The safety of domestic water bodies can not be separated from the service guarantee of various types of ultrafiltration membrane modules. For many companies engaged in the production and manufacturing of ultrafiltration membrane modules, whether they can follow the pace of the times, first of all, the new machinery and equipment in the field is related to the survival of the company.

In the future, the sales market of ultrafiltration membrane filter element will be the world for these companies that are brave in innovation and try new things.