ultrafiltration membrane Processing technology in sewage treatment

1. Resolved before:

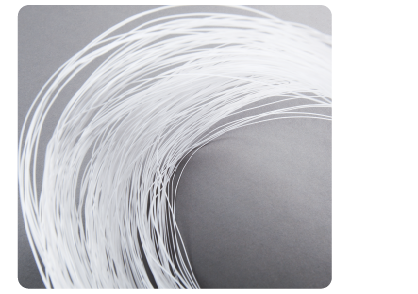

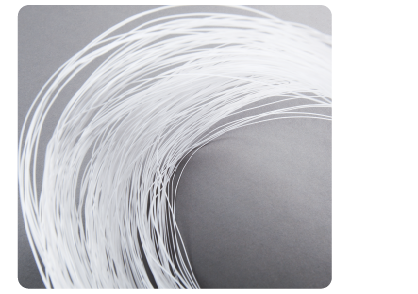

In the whole process of sewage treatment and other industrial production purification treatment, extraction and separation, ultrafiltration membrane method can be used as the preparatory treatment of the whole process of processing technology, and can also be used as a high solution of the whole process of processing technology. In the whole process of widely used sewage treatment process, it is often used as a way of deep cleaning. According to the characteristics of hollow chemical fiber ultrafiltration membrane, there are certain provisions for solution before water supply. As suspended solids, colloids, microbial strains and other sundries in water will attach to the membrane surface, the membrane will suffer environmental pollution. Because the water transmissivity of ultrafiltration membrane is relatively high, the concentration value of intercepted residue on the membrane surface rapidly expands, resulting in the polarization of said concentration value. More serious is that some very fine particles will enter the membrane hole and block the water safety channel. In addition, the microbial strains in the water and the basic metabolic substances to form viscous chemicals will also adhere to the membrane surface. This is due to the decrease of ultrafiltration membrane permeability and the change of separation function. At the same time, water supply temperature, PH value and concentration value of ultrafiltration membrane are also specified to a certain extent. Therefore, proper data pretreatment and water regulation must be carried out for ultrafiltration membrane water supply to meet the specified water supply standards, so as to increase the service life of ultrafiltration membrane and reduce the cost of sewage treatment.

A. Destruction of microbial strains (bacteria, algae):

When the water is rich in microbial strains, some of the intercepted microbial strains are likely to stick to the material surface of the pre-treatment system software, such as the multi-media filter, after adding the pre-treatment system software. The emergence of microbial strains has a very obvious adverse effect on hollow chemical fiber ultrafiltration membrane. The removal of bacteria, algae and other microbial species in raw water must be highly valued. NaClO, O3 and other oxides are usually added in the water treatment technology, and the concentration value is generally 1-5mg/l. In addition, ultraviolet light sterilization can also be applied.

B. Reduce the turbidity of water seepage:

When there are suspended solids, colloids, microbial strains and other sundries in the water, it will make the water turbid to a certain extent. The turbidity will block the light source. This kind of electronic optical effect is related to the amount, size and appearance of the residue.

C. Removal of suspended solids and colloidal chemicals:

Add concentration polarization chemicals (water treatment flocculants) that are opposite to the charge of colloidal particles to the raw water to get rid of the reliability of colloidal particles, so that the synthetic charge balance of colloidal particles with concentration polarization can make the separated colloidal particles coagulate into solid packages, and then use overfiltering or precipitation to better remove them.

D. Removal of soluble organic compounds:

Soluble organic compounds can not be completely removed by foundation settlement of inclined plate sedimentation tank, multi material filtration and ultrafiltration membrane. At present, air oxidation method or absorption method is often used.

(1) Air oxidation method: chlorine or sodium hypochlorite solution (NaClO) is used for air oxidation, which has a good practical effect on the removal of soluble organic compounds. In addition, active oxygen (O3) and potassium permanganate solution (KMnO4) are also good oxides, but the cost is slightly higher;

(2) Adsorption method: use of activated carbon or macroporous adsorption resin can effectively remove soluble organic compounds. However, air oxidation is still needed for alcohols and phenols that cannot be absorbed.

E. Water supply body regulation:

(1) Adjustment of water supply temperature: the full play of water absorption performance of ultrafiltration membrane is related to the temperature at the same time. When the water supply temperature is low, a certain type of temperature raising countermeasures can be selected to make it operate at a higher temperature to improve efficiency. However, when the temperature is too high, it is also bad for the membrane, which will cause the transformation of membrane characteristics. For this matter, refrigeration countermeasures can be selected to reduce the water supply temperature;

(2) Adjustment of water supply PH value: ultrafiltration membranes made of different materials have different application scope for PH value. If water seepage exceeds the application scope, it must be adjusted.